ELASTOHYDRODYNAMIC LUBRICATION (EHL)

Theoretical/numerical studies began in the 70's.

Experimental work has been made since the 80's.

Experimental Research

Optical interferometry is one of the most used technique to determine

the film thickness and shape in typical elastohydrodynamic lubrication (EHL)

conditions. Simulations of real machine contacts, such as those between

rolling elements and races of bearings, are realized using transparent discs

and specimens with proper radii of curvature. White or monochromatic lights

are used to obtain interference patterns from which lubricant film thickness

and shape can be evaluated. This experimental apparatus is a typical interferometric

test rig using both white and monochromatic light. Two motors, one for the specimen and one for the disc, allow to do tests with different rolling

and sliding speed conditions.

The Experimental Apparatus

With the use of two gas bearings tests in

pure rolling conditions (with the disc disconnected from its motor and only

moved by the contact with the specimen) and measure of friction force are

also possible.

The interference patterns are recorded using a video camera

and a recorder; stored images are then discarded in a computer and elaborated with an image processing program developed in the MATLAB environment.

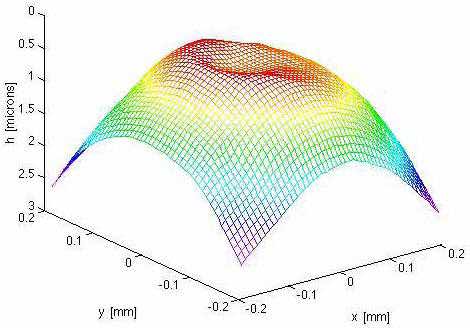

Monochromatic (546nm) Interference Image

and corresponding 3-D Mesh Surface Plot (ball-plane contact)

Last modified on March 28, 1998

This page is created by : Enrico Ciulli

and maintained by Enrico Ciulli, ...